WHAT OUR CAPABILITY

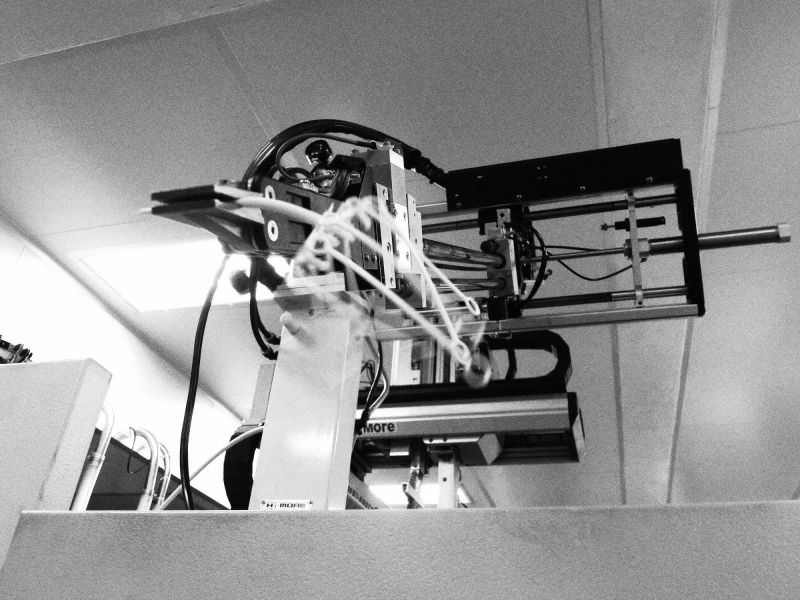

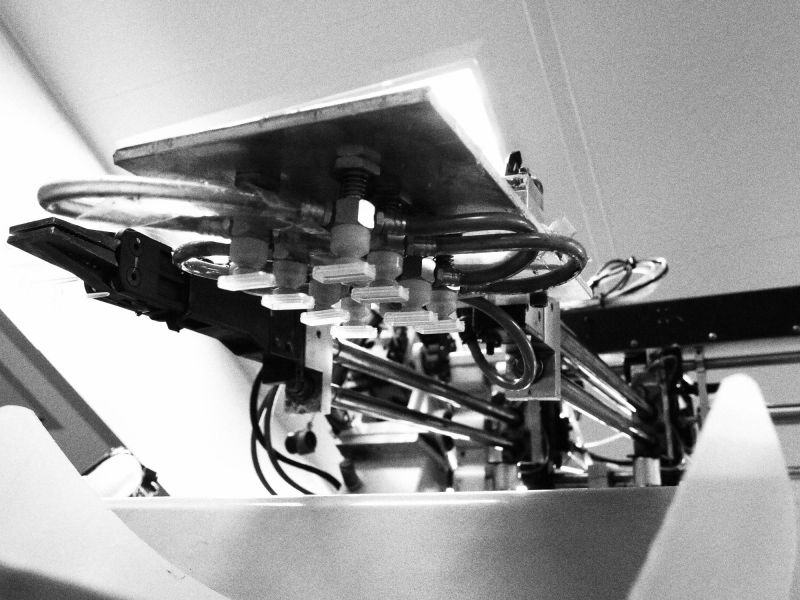

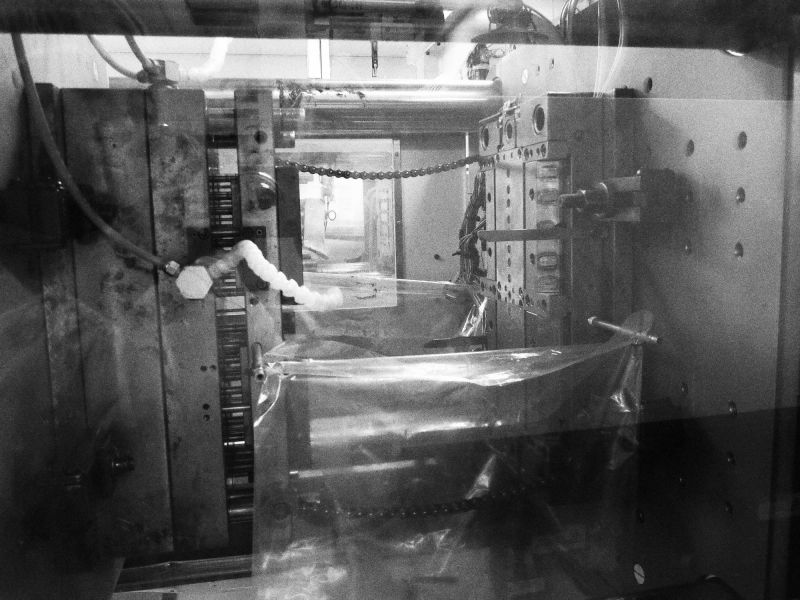

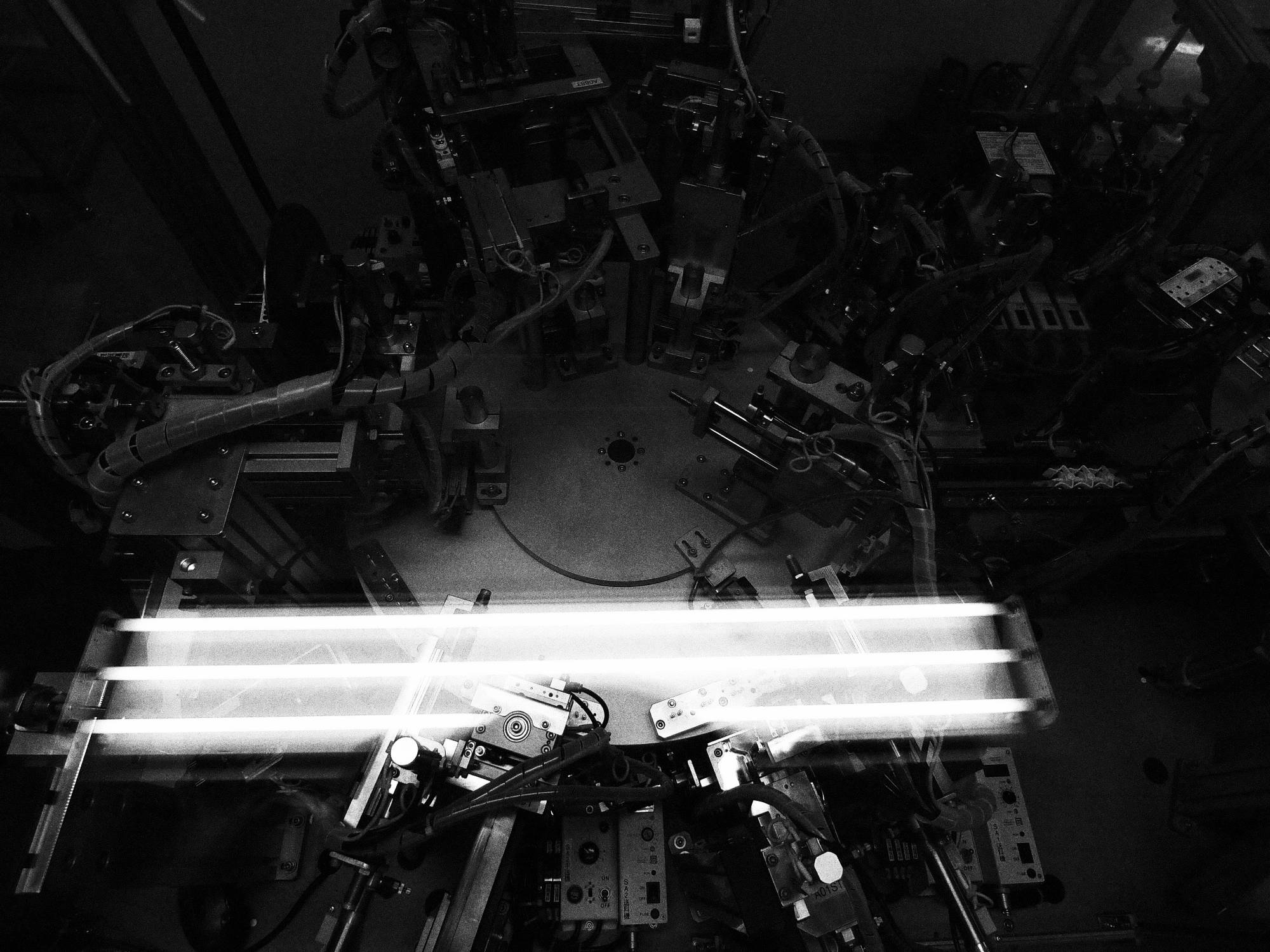

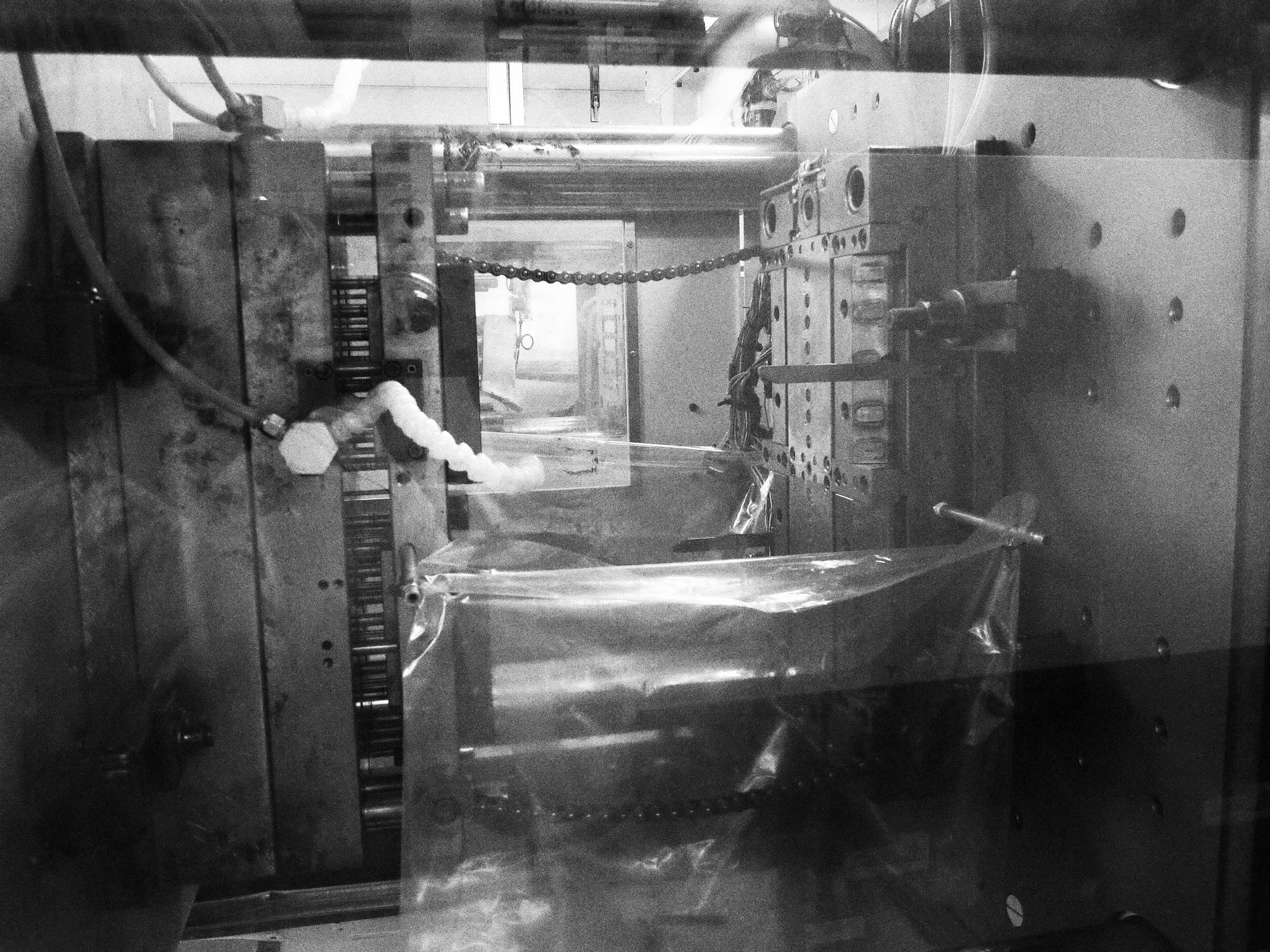

MOLD DESIGN

Established since 1989, have over 30 years of experience of mold manufacturing.

We have made multiple molds for gear parts, medical consumables, medical equipments,

electronic mechanism, stationary and other plastic injection mold.

With all those expertise and wealth of experience, we are confident of mold making.

We can make different kinds of mold products with any functional requirements.

PRODUCT DESIGN & DEVELOPMENT

Product development

Programme costing

Fit for purpose analysis

Material selection: Suitability to meet client specifications, suggestions on alternatives to existing materials.

Simple Mold Flow Analysis

Design for manufacture

Tool, component & device design

CAD modelling

3D modelling (SoildWorks)

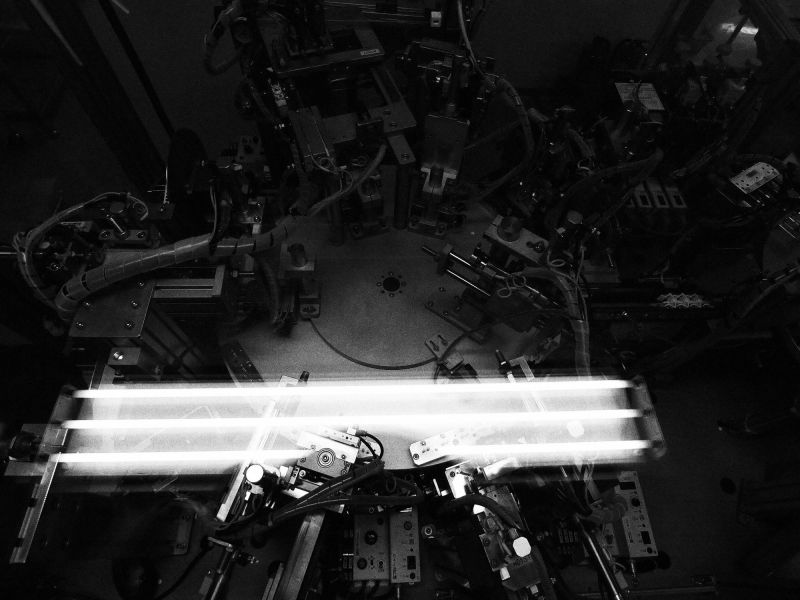

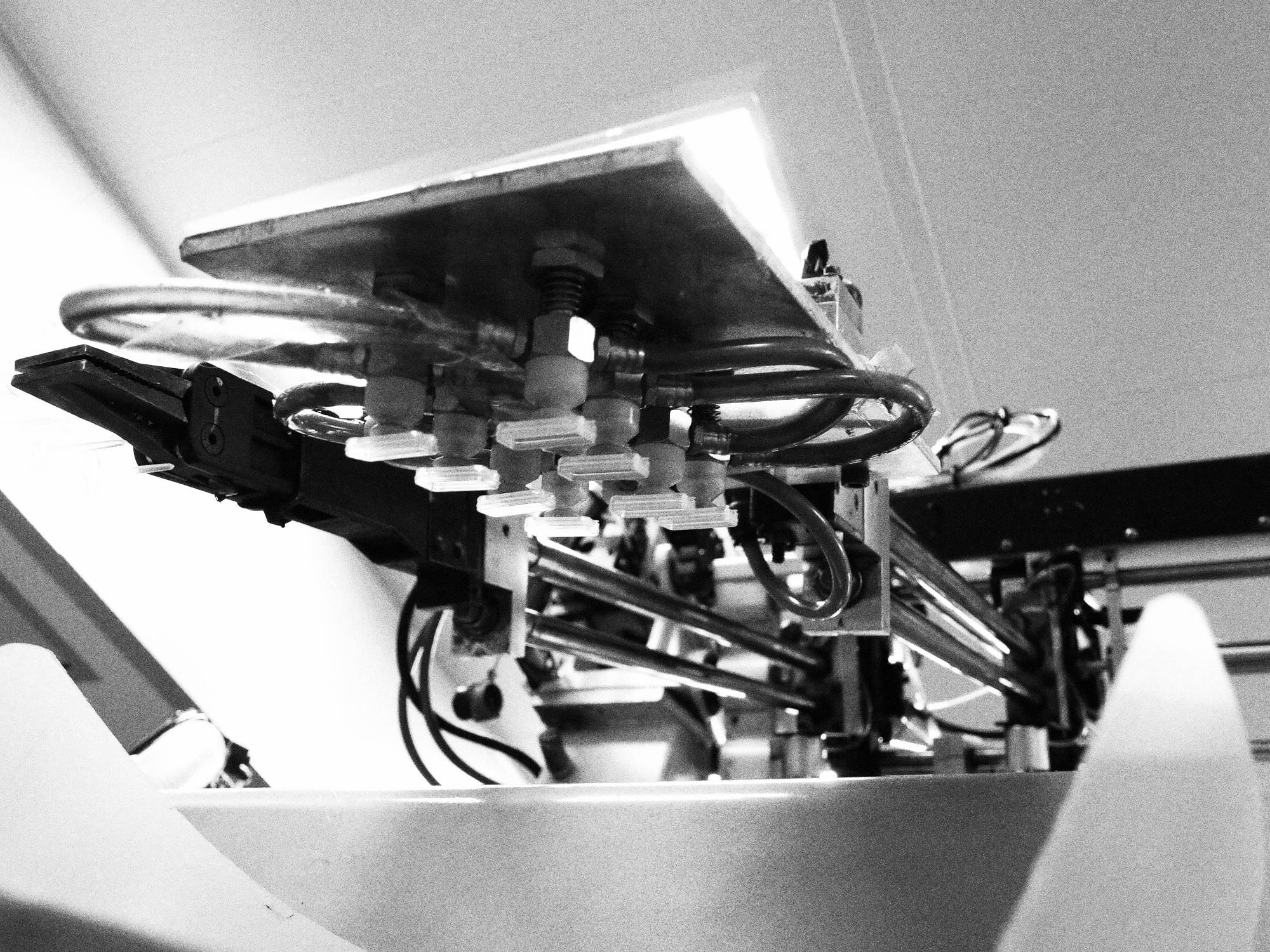

TESTING

Validation Protocols

Design of Experiments

Installation qualification

Operational qualification

Performance qualification

ODM testing

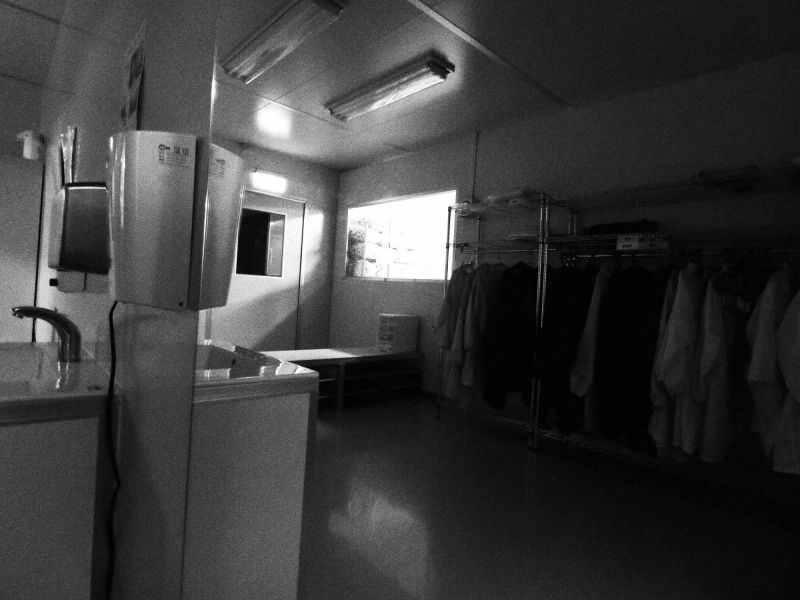

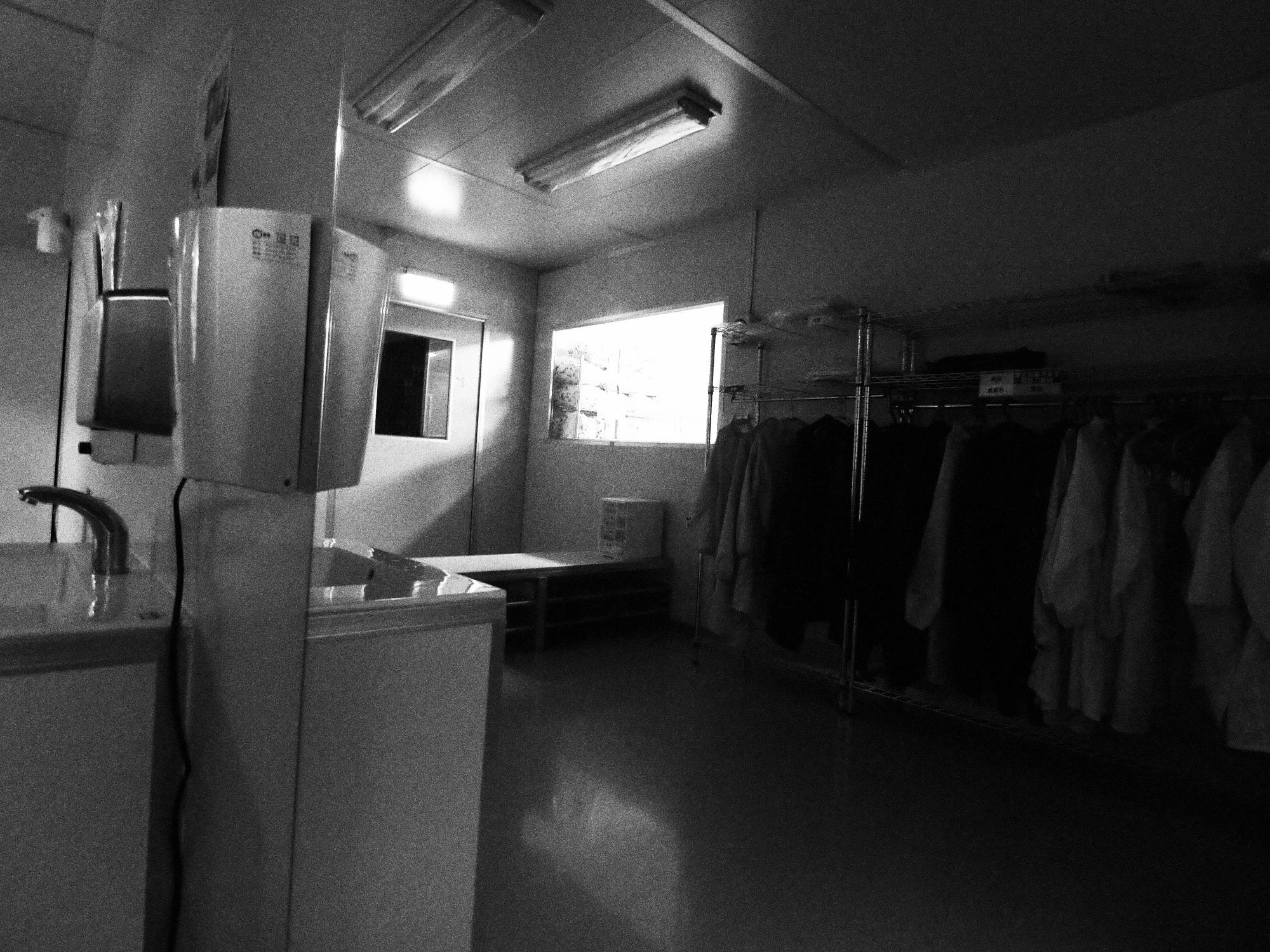

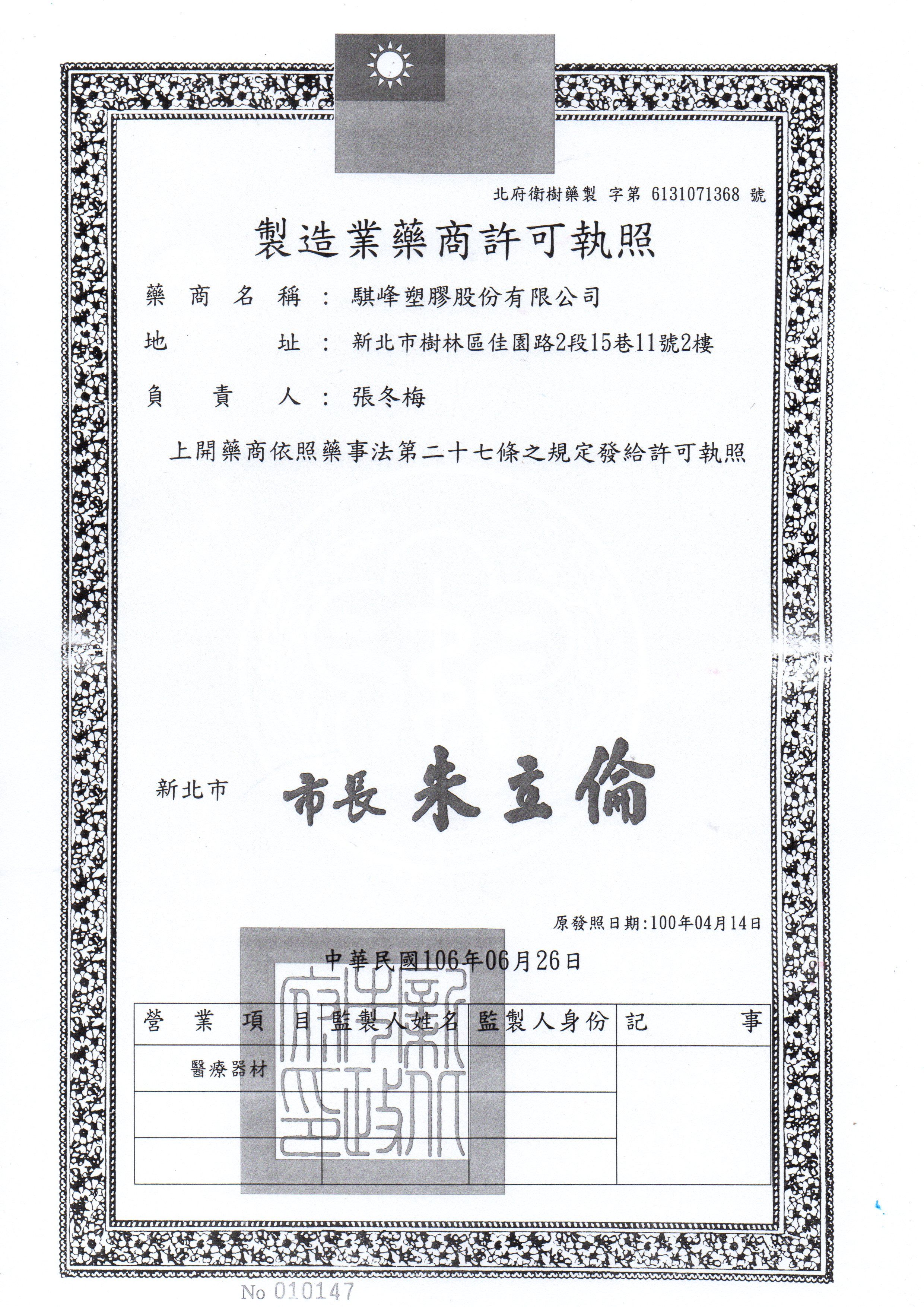

QMS COMPLIANCE

Product master files

Creation of QMS in compliance with ISO 13485

Quality control including testing, porduction, packging, dimension measurement and visual inspection SOPs, Quality Control Plan

Declarations of Conformance to Standards